Production Process

Chemical Vapor Deposition

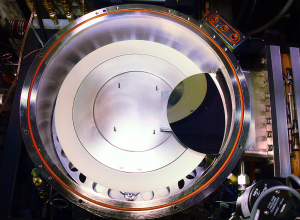

Conformity over complex 3D surfaces – Chemical vapor deposition (CVD) is a thin film deposition technology that provides uniform, dense, high-purity coatings with excellent step coverage and conformity over complex 3D surfaces. CVD reaction parameters allow for control of the coating composition, crystallinity, defect density, and internal stresses.

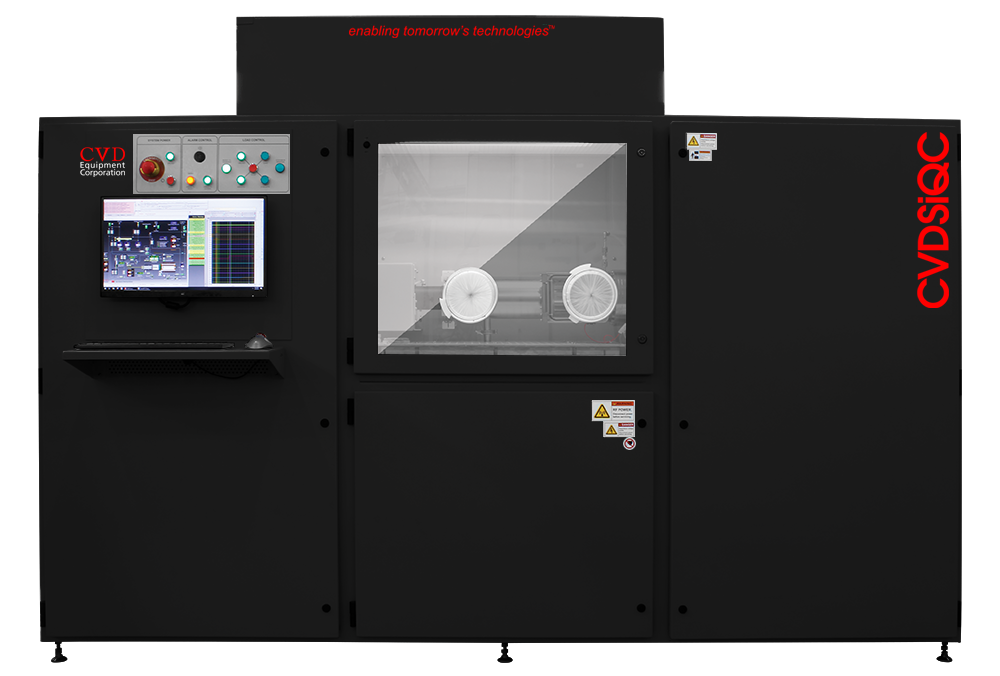

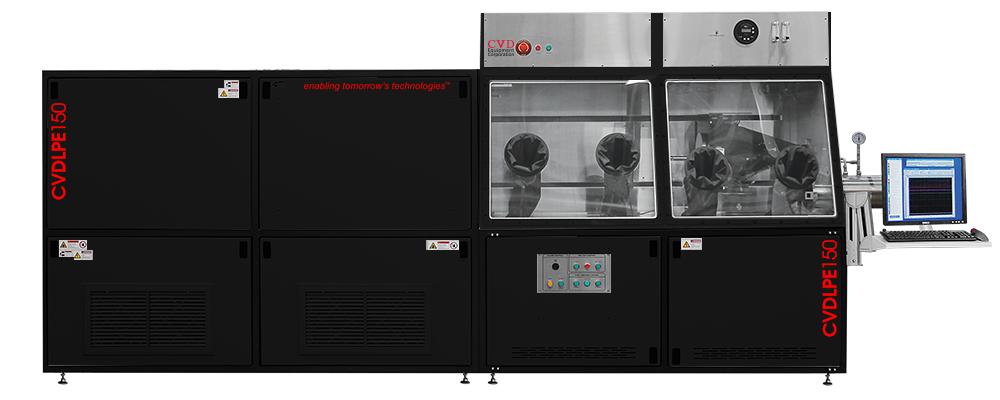

CVD Equipment Coating Systems

PVT Systems

HVPE Systems

LPE Systems

Powder Coat Systems

Fiber Coating Systems

CVI Systems

BondCoat™ Systems

Reel-to-Reel

Cluster Tools

MOCVD Systems

PECVD Systems

Speciality Systems

PROPERTIES & CHARACTERISTICS

Coatings Deposited by Chemical Vapor Deposition Enhance a Component’s Properties and Characteristics

Corrosion protection and barrier layers

Environmental coatings

Antifouling

Encapsulation

Friction/tribology

Wear resistance

Aesthetics/cosmetics

Hydrophobicity/hydrophilicity

Thermal conductivity/insulation

Electrical conductivity/insulation

Catalytic activity

Photon reflectivity/absorbance

Shock absorption

Compressibility

Mechanical bonding/interlocking

Surface or contact area

Fire retardancy

Biocompatibility

Coatings are often designed to perform multiple functions.

TYPES OF INDUSTRIAL COATINGS

OPTICAL PROPERTIES

Photoluminescent Coatings

Antireflective Coatings

Photochromatic Coatings

ELECTRICAL PROPERTIES

Antistatic Coatings

Conductive Coatings

Dielectric Coatings

THERMAL PROPERTIES

Heat Resistant Coatings

Thermal interface Coatings

Intumescent Coatings

STRUCTURAL PROPERTIES

Hard Coatings

Anti-Abrasion Coatings

Anti-Corrosion Coatings

BIOENGINEERED PROPERTIES

Anti-Microbial Coatings

Biocompatible Coatings

Bone Compatible Coatings

PHYSICO-CHEMICAL PROPERTIES

Photocatalytic coatings

Hydrophilic coatings

Hydrophobic Coatings

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”