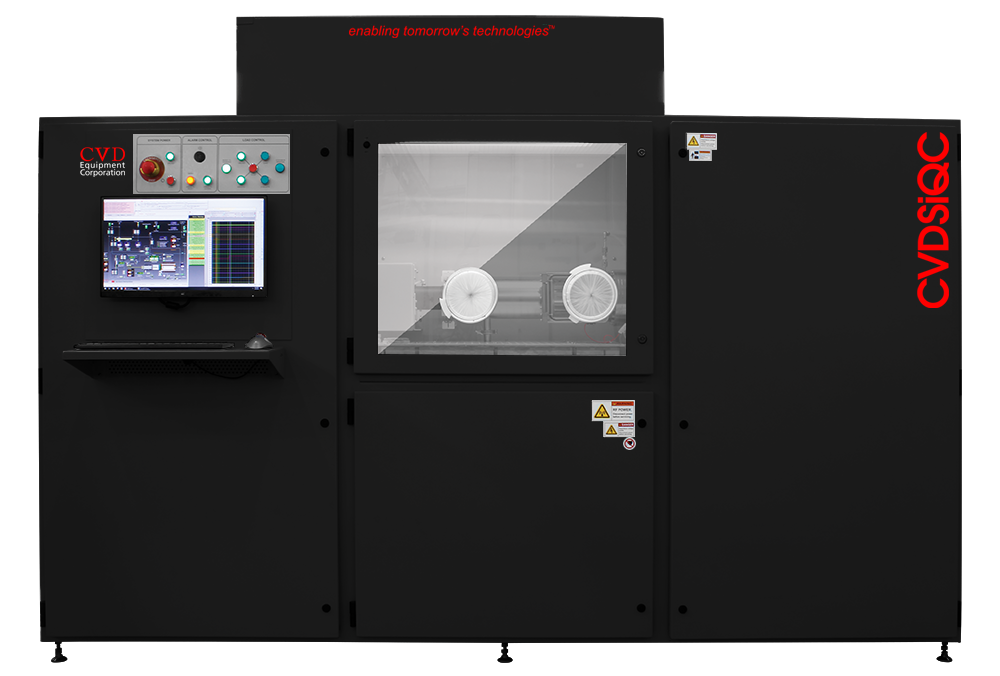

SiQC Systems

Silicon Precursor Quality Control Test Sample Manufacturing System

The Silicon Precursor Quality Control Test Sample Manufacturing System (SiQC) is designed to grow ultra-high-purity (intrinsic) monocrystalline silicon layers on a monocrystalline silicon substrate for qualifying feedstock for Polysilicon manufacturing facilities.

Our SiQC system provides optimum control over Silicon epitaxial thick film grown on the processing of float zone (FZ) wafers. A water-cooled, high-purity quartz process tube is offered to minimize tube deposits by keeping the quartz tube cool even during long deposition runs. Minimum tube deposits allow more runs between tube cleanings.

SiQC System Features & Options

Preprogrammed Recipes for Silicon Epitaxial Deposition

Processes up to two float zone wafers per run

High purity susceptor

Cantilevered automatic substrate loading/unloading system

Loadlock isolates the process tube from ambient atmosphere during loading and unloading

High purity, water-cooled, cold wall quartz process tube

RF induction heating

Process temperatures from 700 °C to 1500 °C

Mass flow controlled gas lines: UHP argon & hydrogen

Integrated vacuum system for evacuation of process tube to a base pressure of <20 mTorr

Application customized safety systems

Comprehensive software and hardware safety interlocks

Hydrogen purifier (20 SLPM capacity) for delivering high-purity hydrogen

CVDWinPrC™ system control software for real-time process control, graphing, data logging, and process recipe editing

Choose one of three options to meet your exact needs:

Continuous Chlorosilane Feed Option (DCS, TCS, SiCl₄), including liquid feed/drain, UHP Argon purge feed line, fluid flow controller, vaporizer, and sample/UHP Argon purge line (vent to scrubber). Allows for real-time characterization of liquid precursor material by sampling the feedstock continuously.

The continuous Silane Feed Option allows for real-time gaseous silane characterization by continuously sampling the feedstock.

Chlorosilane Bubbler Feed Option allows for batch sampling of the feedstock via removable Chlorosilane Bubbler (made of 316 stainless steel electropolished to a 15 ra finish including isolation valves)

Clean hood with iris ports to minimize contamination when loading and unloading test Si wafer(s) with high-purity susceptor

Continuous chlorosilane feed option (DCS, TCS, SiCl₄)

Continuous silane feed option

Chlorosilane bubbler feed option – removable bubbler

powered by CVDWinPrC™

Powered by our CVDWinPrC™ process control software, the systems automatically log data and graphically show time-dependent values of user-selected parameters. CVDWinPrC™ also allows users to load preprogrammed recipes, modify, check, and create new recipes, and view real-time or saved process data.

Safety Protocols

The systems have application configured safety protocols embedded into relay logic, PLC, and CVDWinPrC™ software.

High-Touch Customer Service, Including:

- Site Survey

- Installation Coordination and Field Acceptance

- NRTL/UL/CE Certification Available

- Initial Start-Up Support

- On-Site Training

- Warranty Response and Remote Capability

- Help Desk Support & Customized Service Contract Plans

- Continuous Improvement Programs and Support

- Customized Site Support Contracts

- Spares and Consumables

- Preventative Maintenance

- Site Personnel Contracts

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”