ALD Systems

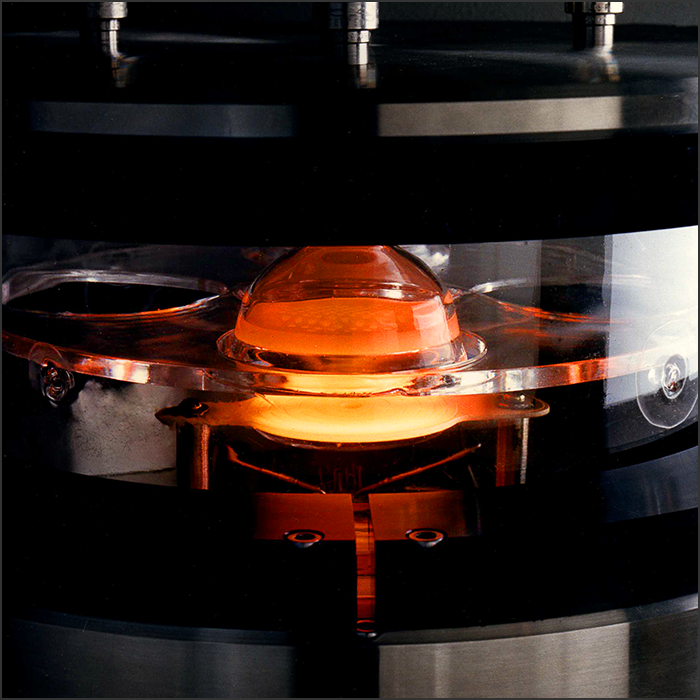

Atomic Layer Deposition (ALD) Systems

ALD is a thin film deposition process that allows for atomic layer thickness resolution, excellent conformity of high aspect ratio surfaces, and pinhole-free layers. This is achieved by the sequential formation of atomic layers in a self-limiting reaction.

ALD is commonly used in the semiconductor industry for high-k dielectric films in CMOS processing, memory devices, MEMS, and sensors. ALD systems are used for the development of protective and functional coatings in fuel cells and other applications requiring corrosion or wear resistance. They are also used to coat high aspect ratio structures like nanowires and nanotubes for next-generation device development.

Oxides: Al2O3, TiO2, SnO, HfO2, ZnO, Fe2O3

Nitrides: TiN, TaN, WN

Metals: Cu, Ru, Ir, W, and more.

powered by CVDWinPrC™

Powered by our CVDWinPrC™ process control software, the systems automatically log data and graphically show time-dependent values of user-selected parameters. CVDWinPrC™ also allows users to load preprogrammed recipes, modify, check, and create new recipes, and view real-time or saved process data.

Safety Protocols

The systems have application configured safety protocols embedded into relay logic, PLC, and CVDWinPrC™ software.

High-Touch Customer Service, Including:

- Site Survey

- Installation Coordination and Field Acceptance

- NRTL/UL/CE Certification Available

- Initial Start-Up Support

- On-Site Training

- Warranty Response and Remote Capability

- Help Desk Support & Customized Service Contract Plans

- Continuous Improvement Programs and Support

- Customized Site Support Contracts

- Spares and Consumables

- Preventative Maintenance

- Site Personnel Contracts

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”