CVI Systems

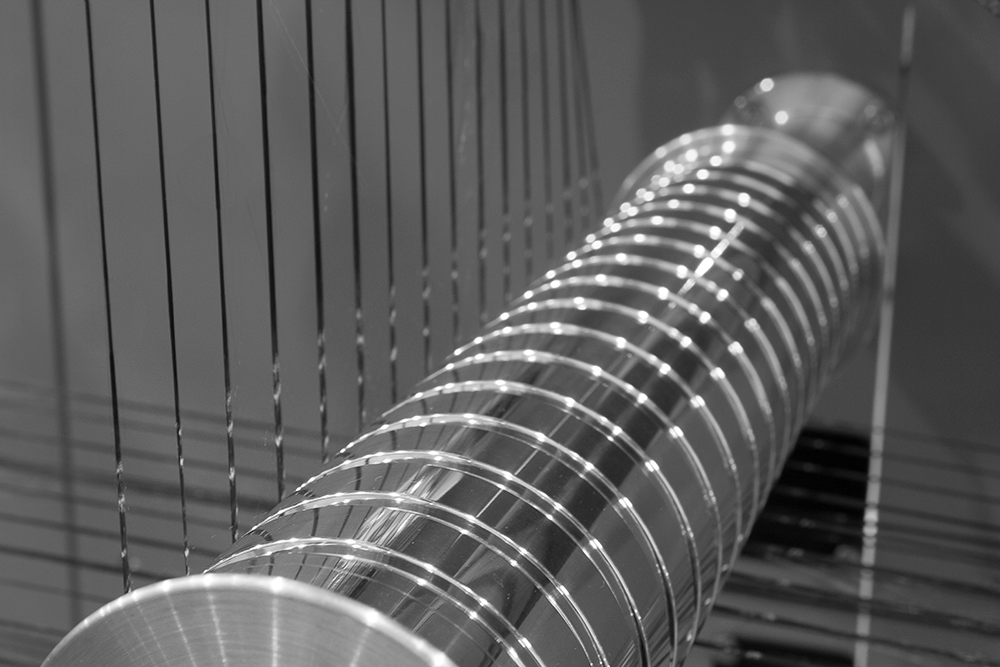

Chemical Vapor Infiltration (CVI) Systems

CVI is a variant of a chemical vapor deposition process that is performed at low pressures to allow for coating the internal surfaces of a porous material. Using heat and low pressure, precursor vapors penetrate the pores/fibers of the material and deposit to form a conformal coating on the internal surfaces.

Our CVI platform is used to coat the internal surfaces of porous materials having complex shapes and geometries. The CVI materials include Carbon, Silicon, Carbides (SiC, BC, TiC, WC), Nitrides (SiN, BN, TiN), Oxides (SiO2, Al2O3), metals (Tantalum), and more. The CVI coating improves the material’s properties from mechanical strength, and oxidation resistance to corrosion resistance, It is widely used in composite materials production, especially for aerospace and medical applications.

CVI is used in the production of biocompatible materials, ceramic matrix composites, carbon/carbon composites, and filtration media.

CVI System Features & Options

Single, Dual, or Multi-Chamber configuration for improved productivity

Substrate temperatures > 1000 °C

Cascade temperature control using external (furnace) and internal (process) thermocouples for real-time continuous in-situ control of temperature profiles

Process pressure control with automatic pressure adjustment during the process to control infiltration and uniformity

Wet scrubbing and neutralization treatment of hazardous process exhaust gasses

powered by CVDWinPrC™

Powered by our CVDWinPrC™ process control software, the systems automatically log data and graphically show time-dependent values of user-selected parameters. CVDWinPrC™ also allows users to load preprogrammed recipes, modify, check, and create new recipes, and view real-time or saved process data.

Safety Protocols

The systems have application configured safety protocols embedded into relay logic, PLC, and CVDWinPrC™ software.

High-Touch Customer Service, Including:

- Site Survey

- Installation Coordination and Field Acceptance

- NRTL/UL/CE Certification Available

- Initial Start-Up Support

- On-Site Training

- Warranty Response and Remote Capability

- Help Desk Support & Customized Service Contract Plans

- Continuous Improvement Programs and Support

- Customized Site Support Contracts

- Spares and Consumables

- Preventative Maintenance

- Site Personnel Contracts

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”