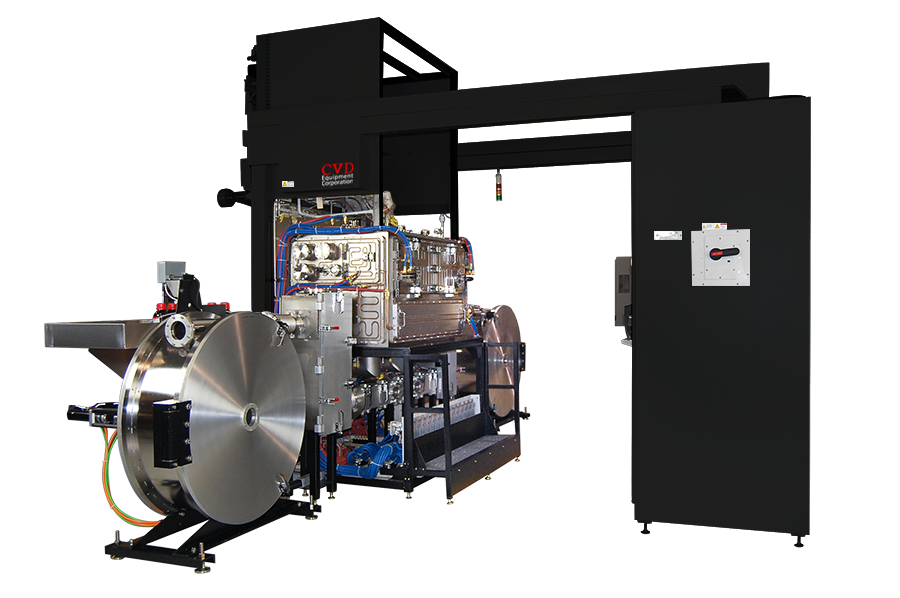

Reel-to-Reel

Continuous Substrate Transport Systems for Volume Production

CVD Equipment Corporation has developed substrate handling systems for many continuous substrate applications such as web (both metal and polymer), tape, and toe/fiber coating substrate material. This capability has enabled our customers to achieve process performance, reliability, and excellent cost of ownership. Our substrate transport and handling systems are suited for use in aerospace, nanomaterial, superconducting tape, ALD encapsulation, and general industrial and microelectronic markets where precision control of alignment and tension at high travel speeds is required.

In general, the transport systems are referred to as “Reel to Reel”, but the technology is much more sophisticated than the term suggests. CVD Equipment Corporation has spent a decade in perfecting the engineering technology and design of the equipment.

Consideration has been made in the following areas:

Wind and Unwind tension control, which is critical for substrate integrity, coating integrity, and coating or process performance and repeatability.

Wind and Unwind substrate alignment to ensure proper positioning and elimination of fraying due to abrasion and wear of the substrate

De-spool and spool modules with drive motors that are isolated from the process environment via magnetically coupled drive shafts

Precision speed control for process performance and thermal considerations.

Computer control of multi-axis wind and unwind reels, transport speed, tension, substrate positioning, and process conditions provides continuous monitoring and storage of all parameters for tracking for quality control and traceability.

Integrated CVD Process Equipment

CVD Equipment Corporation’s reel-to-reel (roll-to-roll) chemical vapor deposition (CVD) process tools deposit materials on a continuous roll of metal foils, plastic sheets, fibers, and other materials in place of individual substrates. The technology has been used for superconductor tape production*, nanomaterial synthesis, aerospace materials, and ALD coatings. Reel-to-reel processing offers high production volumes at a low cost. In-line reel-to-reel processing is often preferred over batch processing for applications where multiple in-line processing steps are required.

We have developed reel-to-reel systems for many applications. Custom systems can be engineered to accommodate various substrate widths and lengths.

Our deposition and infiltration systems for the development and production of CMCs deposit a wide range of materials, including nitrides, carbides, and carbon nanostructures. One example is a continuous production process for chemical vapor infiltration of silicon-doped boron nitride onto individual filaments of multiple parallel processed silicon carbide fiber tows. The Si-doped BN is used as an interphase to control the fiber-matrix bonding and transfer load between the fiber and the matrix in such a way that prevents the brittle fracturing of the CMCs. More technical information about interphase fiber coatings can be found here: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20050179368.pdf

SYSTEM FEATURES & OPTIONS

As a part of our product line, CVD Equipment Corporation supplies continuous reel-to-reel (web, fiber, tape) coating systems that are used in the process development and production of various applications. Our proprietary technology includes:

Atmospheric or low-pressure roll-to-roll and fixed substrate processing systems

Process temperatures >1400 °C

De-spool and spool modules with drive motors that are isolated from the process environment

Intelligent Unwind and Wind – optical sensing and automatic linear actuated positioning for aligning the payout from the bobbins to minimize rubbing/abrasion during payout and spooling.

Low tension closed-loop control – automatic feedback control of tension down to 10 grams

Parallel processing of multiple spools

Multiple process chambers operating in parallel or in sequence to increase production throughput

Full system integration, including fiber handling, deposition chambers, vacuum systems, process gas delivery systems, exhaust gas conditioning systems, and safety & controls systems

Real-time data logging and graphing

powered by CVDWinPrC™

Powered by our CVDWinPrC™ process control software, the systems automatically log data and graphically show time-dependent values of user-selected parameters. CVDWinPrC™ also allows users to load preprogrammed recipes, modify, check, and create new recipes, and view real-time or saved process data.

Safety Protocols

The systems have application configured safety protocols embedded into relay logic, PLC, and CVDWinPrC™ software.

High-Touch Customer Service, Including:

- Site Survey

- Installation Coordination and Field Acceptance

- NRTL/UL/CE Certification Available

- Initial Start-Up Support

- On-Site Training

- Warranty Response and Remote Capability

- Help Desk Support & Customized Service Contract Plans

- Continuous Improvement Programs and Support

- Customized Site Support Contracts

- Spares and Consumables

- Preventative Maintenance

- Site Personnel Contracts

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”