PECVD Systems

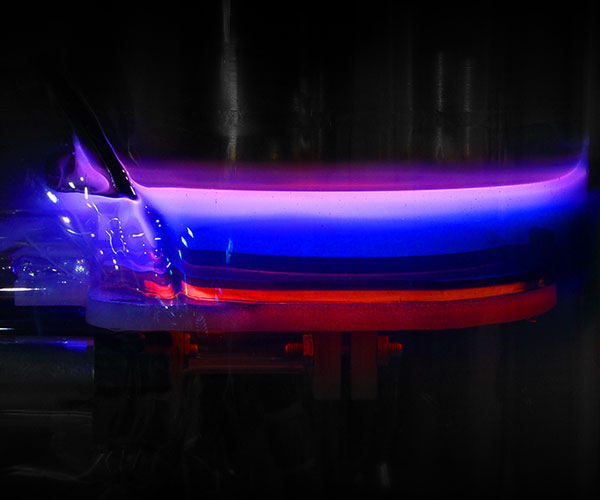

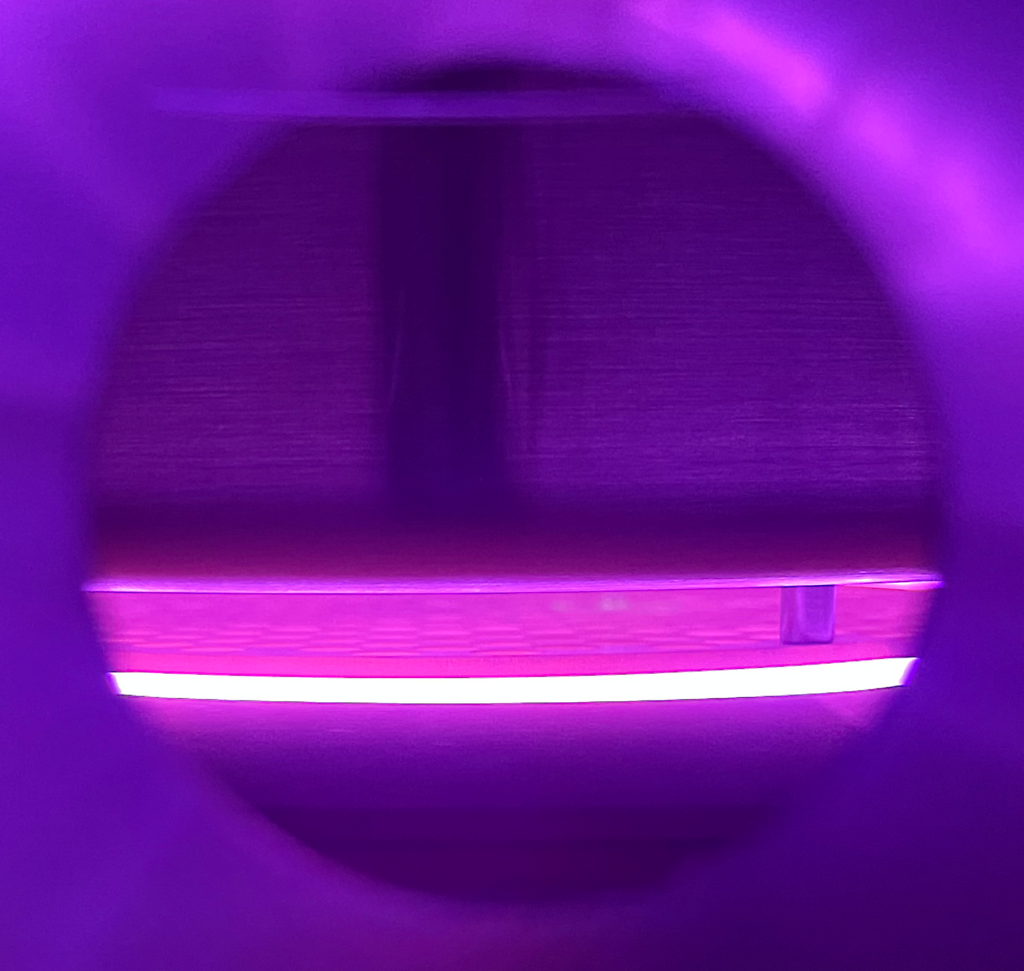

Plasma Enhanced CVD (PECVD) Systems

PECVD is required for the synthesis of many semiconducting and dielectric films. It is also used for industrial coatings where the benefits of CVD are required: conformity, high density, high purity, uniformity, but where the substrate or deposited layers cannot be subjected to high temperatures.

A plasma of the reacting gases is formed in an electric field, either DC or RF, to allow reactions to occur and layers to deposit at lower temperatures. Our PECVD systems are designed and manufactured for industrial applications.

PECVD SYSTEM FEATURES & OPTIONS

Stainless Steel Process Chamber with configurable substrate size

Gate Valve for Compatibility with an Automated Wafer Loading and Unloading Transfer Chamber

Showerhead Gas Delivery

Quartz Liner

Integrated Wafer Lift

Window/Camera to view plasma in the Chamber

Adjustable Gap Between Electrode Grid (Underneath Showerhead) and Substrate from 5mm to 25mm

Wafer Chuck rotation speeds from 10 to 50 rpm

Grounded Wafer Chuck

Top-side Wafer Grounding Capability

Substrate Heating

Multi-zone Heated Wafer Chuck for Temperature Stabilization

Active Wafer Chuck Temperature Stabilization Control is available

We also offer EasyTube® systems through our FirstNano® brand of R&D products for CNT and graphene growth at lower temperatures using inductively coupled plasma.

powered by CVDWinPrC™

Powered by our CVDWinPrC™ process control software, the systems automatically log data and graphically show time-dependent values of user-selected parameters. CVDWinPrC™ also allows users to load preprogrammed recipes, modify, check, and create new recipes, and view real-time or saved process data.

Safety Protocols

The systems have application configured safety protocols embedded into relay logic, PLC, and CVDWinPrC™ software.

High-Touch Customer Service, Including:

- Site Survey

- Installation Coordination and Field Acceptance

- NRTL/UL/CE Certification Available

- Initial Start-Up Support

- On-Site Training

- Warranty Response and Remote Capability

- Help Desk Support & Customized Service Contract Plans

- Continuous Improvement Programs and Support

- Customized Site Support Contracts

- Spares and Consumables

- Preventative Maintenance

- Site Personnel Contracts

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”