Exhaust Gas Conditioning Systems

Exhaust Gas Conditioning Systems

Many processes require the use of hazardous gases which can be flammable, toxic, or pyrophoric. Post process effluent gases also need to be properly treated and neutralized to meet environmental safety standards.

Depending on the type of gases and maximum flow rate, we can provide a burn box, a wet scrubber, or a pyrolizer + wet scrubber two-stage treatment system to treat the waste gases properly before sending it to exhaust. A recirculation and neutralization tank is equipped with a wet scrubber to conserve water usage and neutralize the wastewater. The Exhaust Gas Conditioning Systems can work with our process equipment or independently to treat up to a hundred liters per minute of flammable and corrosive gases.

Our Exhaust Gas Conditioning Systems handle and treat a range of chemistries prior to release. These include:

Hydrogen and hydrocarbons

Ammonia

Chlorine, Chlorides, and Fluorides

Selenides, Sulfides, and Tellurides

Cyanides

Metal Hydrides (Silane, Arsine, Phosphine etc.)

Metal Halides (Silicon Tetrachloride, Tungsten Hexafluoride etc)

Metalorganics (Trimethylgallium, Molybdenum Hexacarbonyl etc)

Organochalcogens

Pyrolizer Burn Box

Thermally decompose explosive, flammable, and pyrophoric exhaust gases. When integrated with our CVD systems, the box can be mounted directly onto the side of the system. The standalone boxes can either be mounted onto a nearby wall or a rack.

Furnace operating temperature up to 900 °C

Quartz reaction tube

Internal baffles for increased reaction surface area

Thermocouple for temperature control and monitoring

Integrated airflow switch

Flammable, explosive, and pyrophoric exhaust gasses/vapors, including:

Hydrogen/Dihydrogen (H2)

Carbon Monoxide (CO)

Acetylene/Ethyne (C2H2)

Ethylene/Ethene (C2H4)

Methane/Methyl Hydride (CH4)

Pyrolizer + Wet Scrubbers

Removes particles from the exhaust stream, reacts moisture-sensitive and air-sensitive exhaust byproducts with water and oxygen in a controlled way, and cools the exhaust gases prior to exiting the system. An optional pH monitoring system can neutralize the scrubbing solution.

Scrubber Models:

610 – Standard

610C – Chalcogen Resistant

610-HCS – High Corrosive Series

1510 – Standard

1510C – Chalcogen Resistant

1510-HCS – High Corrosive Series

1510-HSF – High Saline Flow

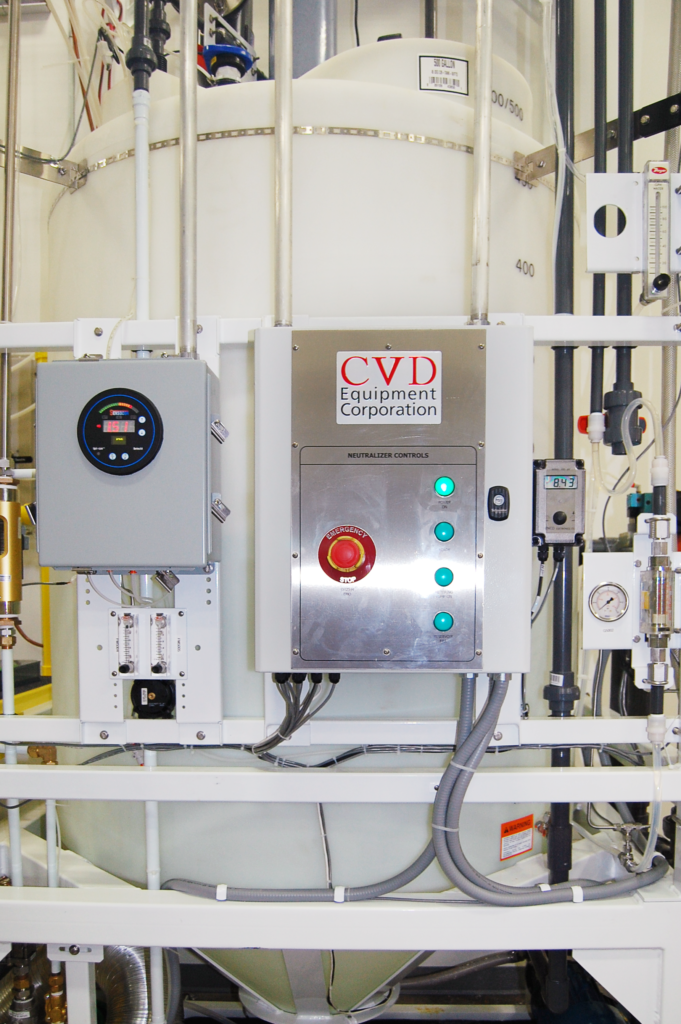

Liquid Neutralizing Systems

For treating corrosive effluent where combustion is not necessary or undesired

Many of our large-scale production CVD systems include liquid-only scrubbing capability. We offer liquid scrubbing solutions as stand-alone units that are customized for the application. Contact the factory for details and pricing.

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”