EasyTube® 3000EXT

Advanced CVD System for University Labs and Industry R&D Facilities

The base system includes a cylindrical quartz process tube which can be from 70 mm to 130 mm ID depending on the desired substrate size. A range of optional modules can be configured to meet the specific requirements of the end user. Many of the options are available as upgrades after installation.

Substrate Sizes Up To 150 mm x 150 mm

Batch processing of multiple wafers per run is also possible

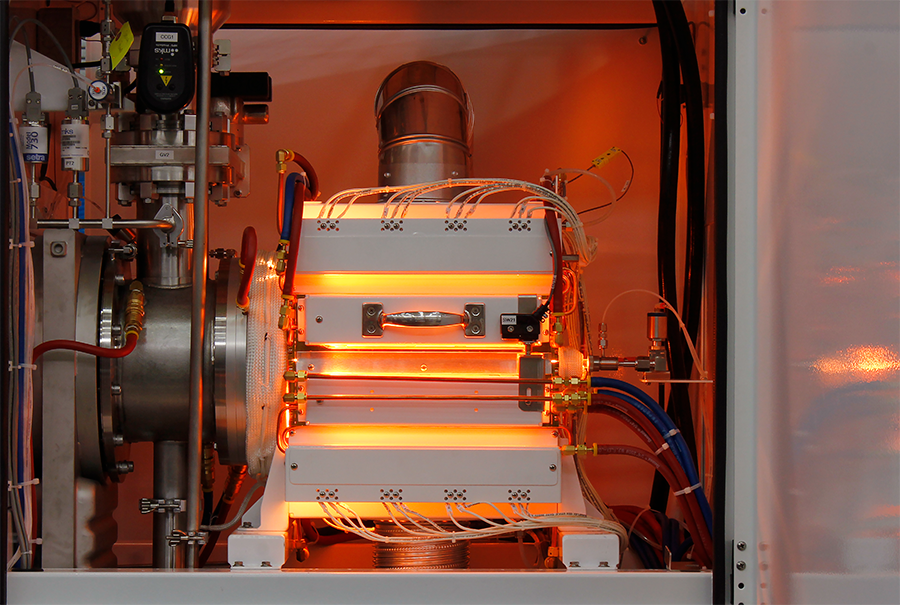

3-Zone Resistance Furnace

Temperatures up to 1200 °C or optional infrared/radio frequency induction heating

Preprogrammed Process Recipes

CVDWinPrC™ system control software

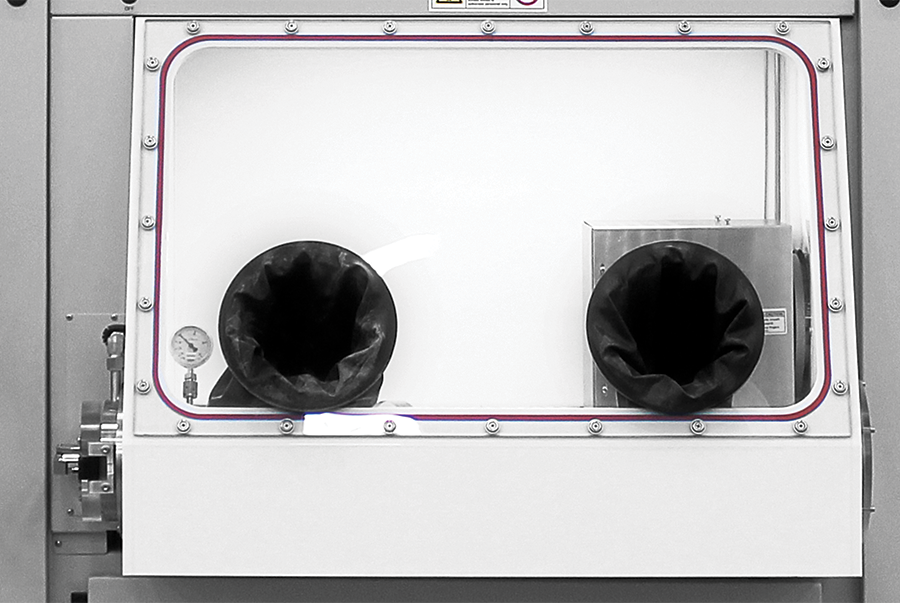

Optional Inert Glovebox

Unloading Sample Under Inert Ambient Conditions

STANDARD FEATURES:

Preprogrammed process recipes

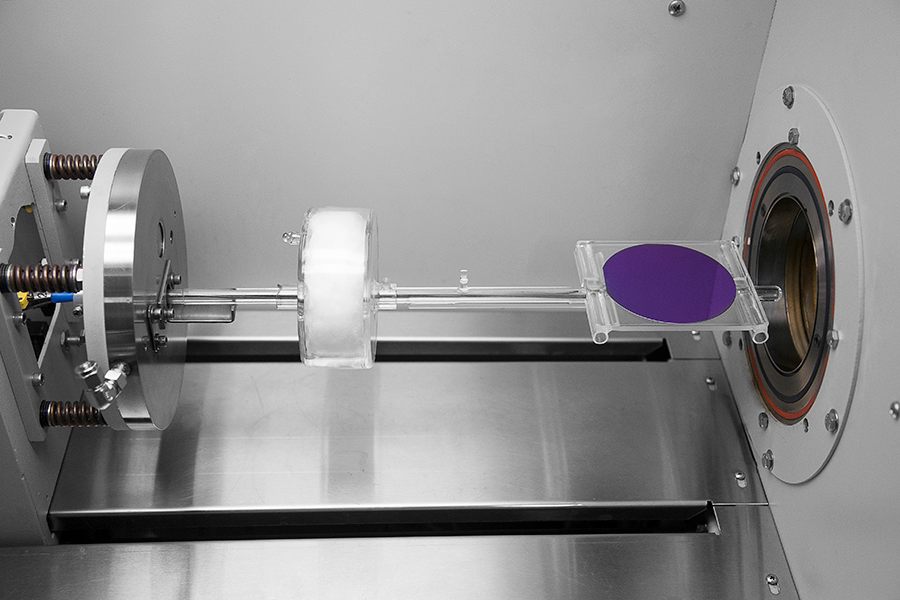

Substrate sizes up to 150 mm x 150 mm (batch processing of multiple wafers per run also possible)

Cantilevered automatic substrate loading/unloading system

Up to 16 mass flow-controlled UHP gas lines

Atmospheric and/or low-pressure process configurations available

3-zone resistance furnace for temperatures up to 1200 °C or optional infrared/radio frequency induction heating

Proprietary real-time cascade process temperature control

High throughput with FastCool™ furnace

User ability to set warnings and alarms

Comprehensive software and hardware safety interlocks

CVDWinPrC™ system control software for real-time process control, data logging, and recipe editing

The EasyTube® 3000EXT model has an extended frame size to accommodate the larger system modules. These can include a glovebox, load-lock, a rolling furnace for rapid heating and cooling, an upstream RF plasma generator, and/or an option to increase the process chamber ID up to 200 mm to accommodate full 6” wafers.

The system is designed to meet today’s safety standards for handling pyrophoric, corrosive, flammable, and toxic gases such as hydrogen, silane, germane, diborane, hydrogen chloride, and metal-organic precursors. The system has application-configured safety protocols embedded into relay logic, PLC, and CVDWinPrC™ software.

EasyTube® 3000EXT Brochure

For a wide range of process configurations and high quality multi-layers

OPTIONS:

High-temperature resistance furnace up to > 1200 °C

Infrared heating for rapid thermal processing > 1100 °C

Radio frequency induction heating for process temperatures > 1500 °C

Upstream plasma

DC bias field assisted growth

Substrate rotation for improved process uniformity

Rectangular process tube for improved laminar gas flow

Liquid/solid source vapor delivery kit

Bubbler liquid auto refill

Glovebox with exhausted N2 or Ar purge

Run/vent: stabilizes gas flows (bypassing the process tube) before flowing into the process tube

Loadlock to isolate the process tube from the ambient atmosphere

High vacuum process chamber and/or load lock chamber

Residual gas analyzer

Air-to-water heat exchanger for cooling water

EasyGas™ hazardous gas cabinets

EasyPanel™ UHP gas panels for argon, nitrogen, helium, oxygen

EasyExhaust™ exhaust gas conditioning system (scrubber/pyrolyzer)

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”