Aerospace and Defense

Aerospace & Defense

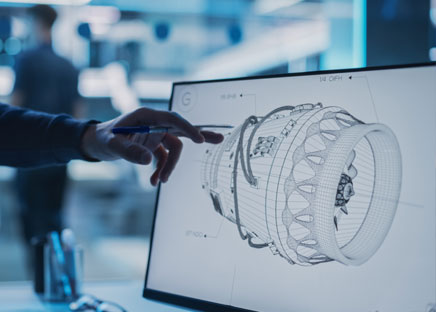

Demand for Ceramic Matrix Composite Materials (CMCs) in gas turbine engines to reduce weight and enable greater fuel efficiency.

Advanced Materials for Aerospace to Enable the Promise of a More Sustainable Future

The aerospace and defense industry strives for perfection in reliability and performance of components and continues to innovate driven by the pressing need for fuel efficiency, modernization, and the growing importance of implementing green technologies to improve air quality, reduce climate impacts and become more energy efficient. Today, researchers are designing lighter and more durable advanced composite materials for application in aerospace to enable the next generation of fuel-efficient aircraft.

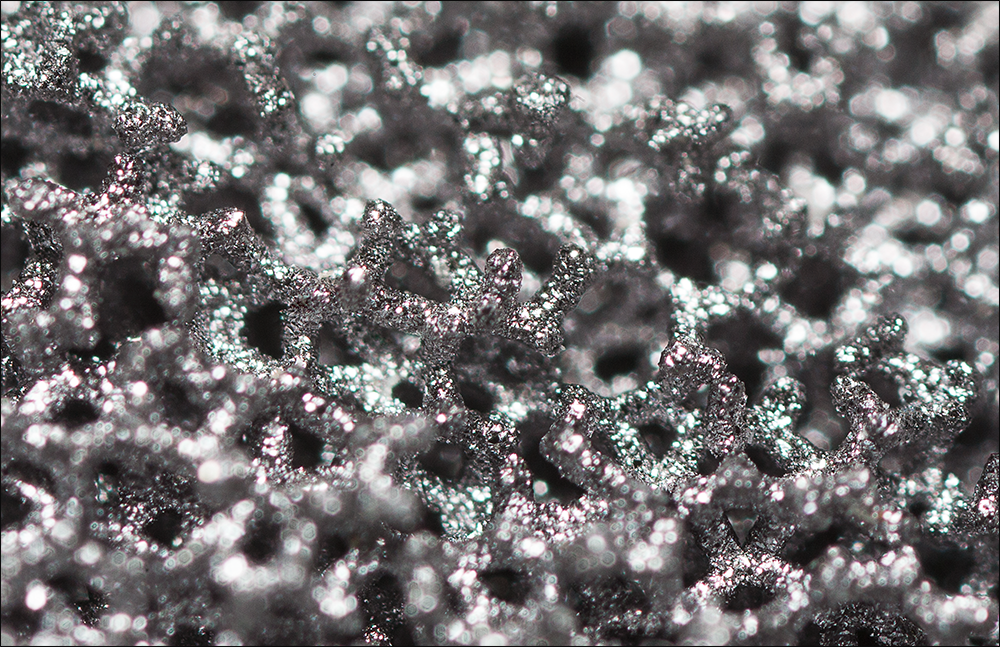

Ceramic Matrix Composites (CMCs): Advanced Materials for Aerospace

CMCs are a group of composite materials consisting of ceramic fibers embedded in a ceramic matrix producing a fiber-reinforced material. An increase in demand for lightweight and fuel-efficient aircraft is driving demand for CMCs in gas turbine engines. Composites comprised of filament materials such as silicon, silicon carbide (SiC), graphite, and boron for example, serve as high strength reinforcing materials that improve the reliability and lifecycle of turbines. With twice the strength and a third the weight of conventional nickel alloys used in standard assembly techniques, CMCs can operate at higher temperatures and reduce fuel consumption up to 2% as they are lighter weight and require less cooling compared to conventional components. Leading aircraft gas turbine engine OEMs (original equipment manufacturers) are adopting CMC components within new engine platforms.

CVD Technology for Deposition and Infiltration of Coatings onto CMC Components

CMCs attempt to retain the desirable properties of ceramics while compensating for their limitations. Designed for enhanced mechanical and thermal properties, CMC’s have high tensile strength at extreme temperatures, lower density, higher toughness, improved thermal stability, lower thermal expansion, better conductivity, lower oxidation, and greater fatigue durability than their ceramic constituents. Coating preforms with high purity, conformal materials tailored with properties for end use specifications makes chemical vapor deposition (CVD) / chemical vapor infiltration (CVI) the preferred technology. Chemical vapor deposition is a thin coating deposition technology that provides uniform, dense coverage, and conformity over complex 3D surfaces using heat and low pressure, under robust process controls. Many steps in the CMC production process involve CVD techniques. CVD Equipment is a trusted supplier to the aerospace and defense industry for process equipment for CMCs. Materials.

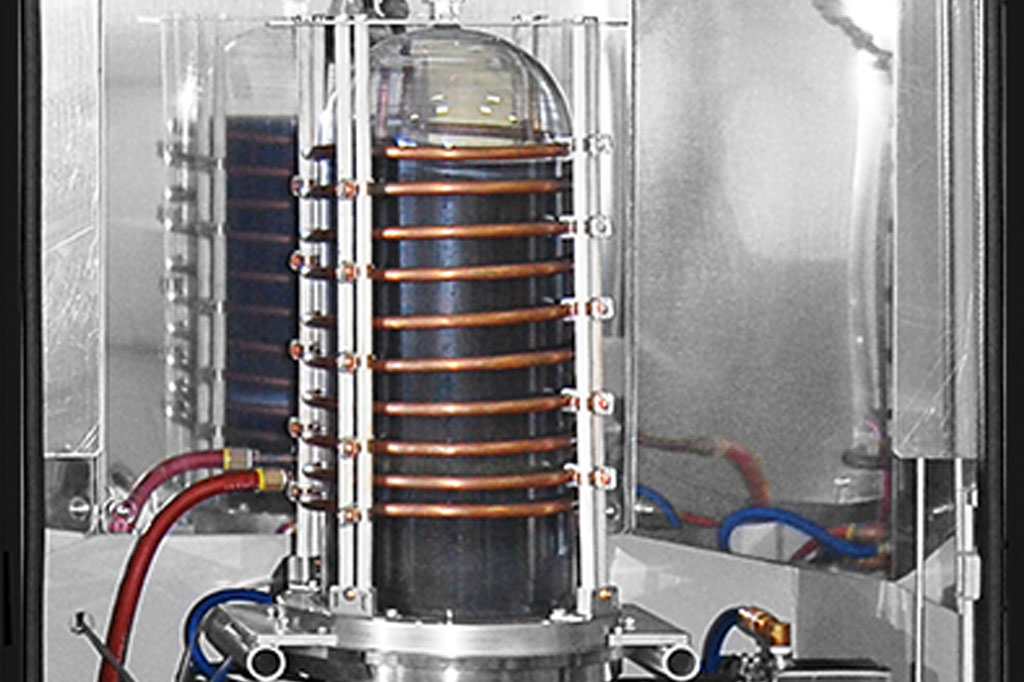

CVDE’s Silicon Bond Coat Production Systems for Coating onto CMC Components

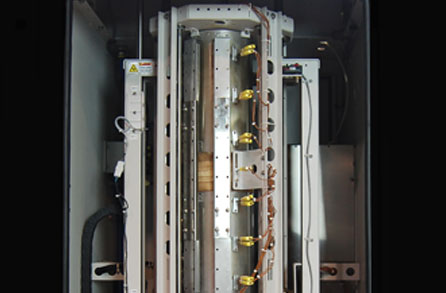

CVD Equipment is a supplier of low pressure CVD tools and production furnaces to coat CMC components with silicon. Our low pressure CVD tools allow for the control of coating composition, crystallinity, defect density, and internal stresses. With RF induction and graphite resistive heating options, and process temperatures of up to 2200°C, our systems include substrate handling, deposition chambers, vacuum systems, exhaust gas conditioning systems, process controls, and safety systems.

CVDE’s CVI Systems for Infiltration of Coatings onto CMC Components

Chemical Vapor Infiltration is a type of CVD process that is used to coat the internal surfaces of a porous material. Using heat and low pressure, precursor vapors penetrate the pores or fibers of the substrate material, and under highly controlled thermodynamic and chemical kinetic conditions, they deposit to form a conformal coating on the internal surfaces. CVDE’s low pressure CVD tools coat gas turbine engine components with silicon, silicon nitride, boron nitride, silicon carbide, carbon, etc. with multi-chamber deposition systems for increased throughput. RF induction and graphite heating options can achieve process temperatures up to 2200 °C. CVD Equipment has a longstanding history supplying low pressure CVD tools and production furnaces to the aerospace industry.

CVDE’s Fiber Coat Production Systems for Deposition/Infiltration onto Carbon and SiC Fibers

Carbon and SiC Fiber Coating Systems for gas turbine engine applications. CVD Equipment provides state-of-the-art production Fiber Coating systems for the aerospace and defense industry. Our substrate transport and handling systems are suited for use in aerospace where precise tension and alignment control are required. Our systems provide infiltration of coatings onto carbon and SiC fibers to control fiber-matrix bonding and load transfer. CVDE’s Fiber Coat Systems allow for 1-tow, 10-tow, and 72 tow configurations for in-line deposition of coatings onto silicon carbide and carbon fibers with our patented fiber handling and transport systems with precise speed and tension control. CVD Equipment’s fiber coating equipment supports the growing demand for CMC materials for commercial and military engine applications.

CVD BondCoat™ System Features & Benefits:

Uniform Silicon Coating (uniform polycrystalline silicon layer onto 3D surfaces)

Up to three Chambers with Single Part Sequential Processing

Multiple gas injectors with independent flow control for thickness uniformity

Capable of direct liquid injection, bubbler source injection, and vapor/gas delivery

Automatic or manually sequenced system for optimum control over deposition (typical component dimensions 4.75″ diameter, 7.5″ tall, customizable)

Substrate Rotation for improved deposition uniformity

Vertical Process Tubes

Single or Multi-zone Furnace (Resistive or RF induction heated)

– Temperatures up to 2200° C

Robust Production System with Enhanced Process Controls

– Temperature Control +/- 0.5° C

– Pressure controls +/- 1%

Optional Gas Delivery Cabinets

Exhaust Gas Scrubber (EGS)

Designed for ease of maintenance

MES Compatible

CVDWinPrC™ system control software for real-time process control, graphing, data logging, and process recipe editing

Fiber Coat System Features & Benefits:

Atmospheric or low pressure roll-to-roll and fixed substrate processing systems

Process temperatures >1400 °C

High Temperature, RF Induction Heating up to 2500°C

De-spool and spool modules with drive motors that are isolated from the process environment

Intelligent Unwind and Wind – optical sensing and automatic linear actuated positioning for aligning the payout from the bobbins to minimize rubbing/abrasion during payout and spooling.

Low tension closed-loop control – automatic feedback control of tension down to 10 grams

Parallel processing of multiple spools

Multiple process chambers operating in parallel or in sequence to increase production throughput

Full system integration, including fiber handling, deposition chambers, vacuum systems, process gas delivery systems, exhaust gas conditioning systems, and safety & controls systems

Real-time data logging and graphing

Productivity support with tailored service contracts

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”